Are you tired of buying pre-shredded tobacco? Do you want to create your own blends and get the perfect shred every time? Look no further than expanded shredded stems tobacco! In this article, we’ll explore the art of processing expanded shredded stems tobacco, from the science behind it to the best equipment to use. Discover the history and future of this unique tobacco variety, and learn about the different varieties and how to mix them to create the perfect blend. Follow our top 10 tips for processing expanded shredded stems tobacco and achieve the perfect shred every time.

Expanded Shredded Stems Tobacco: A Revolutionary Tobacco Product

Tobacco is a plant that has been used for centuries for its medicinal and recreational properties. Over the years, the tobacco industry has evolved, and new products have been developed to meet the changing needs of consumers. One such product is expanded shredded stems tobacco, an innovative tobacco product made from the stems of the tobacco plant. In this article, we will explore the process of producing expanded shredded stems tobacco, the benefits of using it, the history of the product, the different varieties available, the science behind it, its impact on the tobacco industry, and its future.

The Process of Producing Expanded Shredded Stems Tobacco

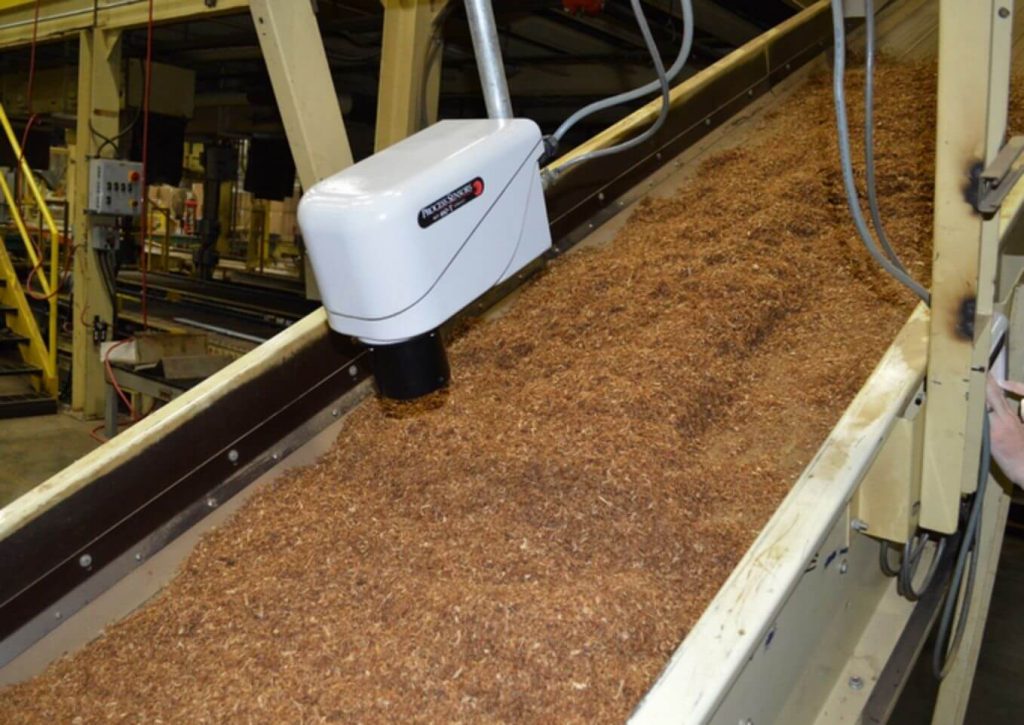

Expanded shredded stems tobacco is made by expanding the stems of the tobacco plant. The stems are heated to a specific temperature and pressure, causing them to expand and become more porous. This process increases the filling capacity of the tobacco, making it more cost-effective and consistent in blend. Once the stems have been expanded, they are shredded into cut tobacco stems or made into reconstituted tobacco sheet to provide a tobacco material of excellent filling capacity.

The Benefits of Using Expanded Shredded Stems Tobacco

Expanded shredded stems tobacco has several benefits over traditional tobacco products. First, it is more cost-effective than other tobacco products, as it reduces waste and provides a consistent blend. Second, it has an improved filling capacity, which means that less tobacco is needed to fill a cigarette. This reduces the amount of tobacco used in each cigarette, making it a healthier option. Third, it provides enhanced flavor, which is a result of the expanded stems’ increased surface area.

The History of Expanded Shredded Stems Tobacco

Expanded shredded stems tobacco has been around for several decades, but it has only recently gained popularity in the tobacco industry. The product was first developed in the 1970s as a way to reduce waste and improve the filling capacity of cigarettes. Over the years, the product has evolved, and new varieties have been developed to meet the changing needs of consumers.

The Different Varieties of Expanded Shredded Stems Tobacco

There are several different varieties of expanded shredded stems tobacco available, each with its unique characteristics. Bright tobacco is typically viewed as producing acidic smoke, while air-cured tobacco is typically viewed as producing basic smoke. Oriental tobacco is known for its unique flavor, while Perique tobacco is known for its spicy flavor. Latakia tobacco is known for its smoky flavor and is often used in pipe tobacco blends.

The Science Behind Expanded Shredded Stems Tobacco

The chemical composition of expanded shredded stems tobacco is different from that of traditional tobacco products. The stems are poorer in alkaloids and other nitrogen compounds, ether extracts, saccharides, and the like, while richer in cell membrane substances such as cellulose, pentosans, etc. The impact of expanded shredded stems tobacco on cigarette smoke emissions has been extensively studied, and it has been found that cigarettes containing expanded shredded tobacco stems produce lower levels of carbon monoxide and hydrogen cyanide.

The Impact of Expanded Shredded Stems Tobacco on the Tobacco Industry

Expanded shredded stems tobacco has had a significant impact on the tobacco industry. The product has been used in cigarette manufacturing for several decades, and it has helped reduce waste and improve the filling capacity of cigarettes. The product has also been used in other tobacco products, such as pipe tobacco blends and cigar fillers.

The Future of Expanded Shredded Stems Tobacco

The future of expanded shredded stems tobacco is bright. The product has several potential uses, including in the production of other tobacco products and as a source of biomass. The product is also environmentally friendly, as it reduces waste and provides a consistent blend. As the tobacco industry continues to evolve, expanded shredded stems tobacco is likely to play an increasingly important role.

What is expanded shredded stems tobacco and how is it made

Expanded shredded stems tobacco is an innovative tobacco product made from the stems of the tobacco plant. The process of producing expanded shredded stems tobacco involves subjecting the tobacco stems to a combination of heat and pressure, causing them to expand. The resulting expanded stems are shredded into cut tobacco stems or made into reconstituted tobacco sheet to provide a tobacco material of excellent filling capacity . The expansion of tobacco stems involves the application of heat and pressure. This process increases the stems’ volume, reduces their nicotine content, and makes them suitable for use in the production of reconstituted tobacco . The process of expanding tobacco stems is usually carried out in tobacco processing facilities . The resulting expanded stems are shredded into cut tobacco stems or made into reconstituted tobacco sheet to provide a tobacco material of excellent filling capacity. The process of producing expanded shredded stems tobacco has been extensively studied, and it has been found that cigarettes containing expanded shredded tobacco stems produce lower levels of carbon monoxide and hydrogen cyanide .

What are the potential economic benefits of using recon tobacco in cigarette production

Reconstituted tobacco, which uses expanded shredded stems tobacco, can make up to 30% of some raw materials . The use of recon tobacco in cigarette production can have several potential economic benefits, including: – Cost-effectiveness: The use of recon tobacco can reduce the cost of cigarette production by utilizing a byproduct of the tobacco plant that would otherwise be discarded .

- Improved filling capacity: Expanded shredded stems tobacco has excellent filling capacity, making it a valuable ingredient in cigarette production .

- Enhanced flavor: The use of recon tobacco can enhance the flavor of cigarettes .

- Reduced waste: The use of recon tobacco reduces waste in the tobacco industry by utilizing a byproduct of the tobacco plant that would otherwise be discarded .

- Increased yield: The expansion of tobacco stems directly influences the yield of tobacco products .

Conclusion

Expanded shredded stems tobacco is a revolutionary tobacco product that has been around for several decades. The product has several benefits over traditional tobacco products, including cost-effectiveness, improved filling capacity, and enhanced flavor. The product has had a significant impact on the tobacco industry, and its future is bright. As the tobacco industry continues to evolve, expanded shredded stems tobacco is likely to play an increasingly important role.

FAQs:

- What is expanded shredded stems tobacco?

- How is tobacco stems expanded?

- Where is the process of expanding tobacco stems carried out?

- What are the benefits of using expanded shredded stems tobacco?

- What are the different varieties of expanded shredded stems tobacco?

- What is the chemical composition of expanded shredded stems tobacco?

- How does expanded shredded stems tobacco impact cigarette smoke emissions?

- What are the effects of additives on expanded shredded stems tobacco?

- How has expanded shredded stems tobacco impacted the tobacco industry?

- What is the future of expanded shredded stems tobacco?

- What is the process of producing expanded tobacco stems?

- What are the characteristics of stem shreds converted from stems?

- What is the method of producing expanded tobacco stems for tobacco cut filler?

- What is the impact of different stem treatments on mainstream smoke emissions and main physical characteristics of the cigarette?

- What are the deliveries of tar, nicotine, phenol, CO, and HCN in the smoke of ESS cigarette?

Answers: – Expanded shredded stems tobacco is an innovative tobacco product made from the stems of the tobacco plant.

- Tobacco stems are expanded through a process that involves the application of heat and pressure, causing the cellular structure of the stems to expand.

- The process of expanding tobacco stems is usually carried out in tobacco processing facilities.

- The benefits of using expanded shredded stems tobacco include cost-effectiveness, improved filling capacity, and enhanced flavor.

- The different varieties of expanded shredded stems tobacco include bright tobacco, burley tobacco, oriental tobacco, perique tobacco, and latakia tobacco.

- The chemical composition of expanded shredded stems tobacco is different from that of traditional tobacco products.

- Cigarettes containing expanded shredded tobacco stems produce lower levels of carbon monoxide and hydrogen cyanide.

- Tobacco additives that are bases increase ?fb values in mainstream smoke.

- Expanded shredded stems tobacco has had a significant impact on the tobacco industry, reducing waste and improving the filling capacity of cigarettes.

- The future of expanded shredded stems tobacco is bright, with potential uses in the production of other tobacco products and as a source of biomass.

- The process of producing expanded tobacco stems involves treating the stems under specified temperature, pressure, and other conditions.

- Stem shreds converted from stems have low filling power, insufficient aroma, high irritation, low strength, and strong wood taste.

- The method of producing expanded tobacco stems for tobacco cut filler involves rolling tobacco stems to a rolled thickness of 0.1 to 0.5 mm.

- The impact of different stem treatments on mainstream smoke emissions and main physical characteristics of the cigarette were investigated, and the results showed that cigarette containing ESS delivered more tar, nicotine, and phenol, less CO and HCN comparing with cigarette containing ECS or ECRS.

- When the proportion of stem material in cigarette blend was 20%, the deliveries of tar, nicotine, and phenol in the smoke of ESS cigarette increased by 6.3%, 11.2%, and 10.8%, while the deliveries of CO and HCN reduced by 11.6% and 3.4%, respectively, compared with ventilation rate and the cigarette.

Books:

- Tobacco: Production, Chemistry, and Technology by Davis and Nielsen

- Tobacco: The Growing and Manufacturing of Tobacco for Human Consumption by Davis

- Tobacco: A Cultural History of How an Exotic Plant Seduced Civilization by Gately